Why Proper Pole Selection is Critical for Project Success

Step 1: Define the Pole's Primary Purpose and Application

The foundation of successful pole selection begins with clearly defining your project's specific requirements. Different applications demand distinct pole characteristics, from height and material selection to mounting methods and aesthetic considerations.

Application specificity drives every subsequent decision in the pole selection process. A pole suitable for residential pathway lighting will not meet the structural demands of a major sports facility or highway installation.

What is the specific application?

Street and Roadway Lighting

Street lighting poles typically range from 15-20 feet for narrow residential streets to 25-50 feet for major roadways. These installations require poles capable of supporting substantial luminaire loads while withstanding constant vibration from traffic.

Car Park Illumination

Commercial car parks commonly use 20-25 foot poles with multiple luminaires per pole. The standard configuration involves:

- 2 luminaires per pole for standard heights

- 4 luminaires for poles exceeding 25 feet in height

Sports Field Lighting

LED sports lighting solutions require specialized considerations:

- Tennis courts typically need 22.8-foot light heights

- Achieved with 20-foot poles plus adapters

- Baseball and other ball field lighting usually starts at 40 feet

- Major facilities can exceed 70 feet for optimal coverage

Pathway and Public Space Lighting

Pedestrian areas use shorter poles, typically ranging from 9-14 feet in height. These installations prioritize:

- Human scale proportions

- Glare reduction

- Aesthetic integration with surrounding landscapes

Decorative and Architectural Poles

Historic districts and premium developments often require custom pole designs that:

- Complement existing architecture

- Meet modern lighting standards

- Satisfy safety requirements

Utility and Multi-function Poles

Modern smart city initiatives increasingly demand poles capable of supporting multiple technologies:

- Lighting systems

- Security cameras

- Environmental sensors

- Wireless equipment

- Digital signage

What are the height and scale requirements?

Light Spread and Uniformity Considerations

Pole height directly influences light distribution patterns:

- Taller poles disperse light over larger areas

- May create uniformity challenges

- General rule: pole spacing should not exceed 3-4 times the mounting height for optimal uniformity

Glare Reduction Strategies

Proper height selection minimizes glare while maintaining adequate illumination levels:

- Lower mounting heights reduce glare

- Require more poles for equivalent coverage

- Impact project economics

Scale Relationships

- Pedestrian Scale: 9-14 feet for pathways and small areas

- Vehicular Scale: 20-30 feet for roads and large car parks

- Sports Scale: 40-100+ feet for athletic facilities

- Highway Scale: 30-50+ feet for major roadways

Regulatory Height Considerations

Local council regulations often specify maximum pole heights for different zoning areas:

- Residential zones typically limit heights to preserve neighbourhood character

- Commercial and industrial zones allow greater flexibility

How will lighting technology influence pole choice?

LED Efficiency Impact

Modern LED technology has revolutionized pole requirements:

- LED luminaires typically weigh 50-70% less than equivalent HID fixtures

- Allow for lighter pole construction

- Enable increased luminaire capacity per pole

Smart Controls Integration

Advanced lighting controls require additional mounting provisions:

- Sensors and controllers

- Communication equipment

- Weather protection systems

- Serviceability access

Solar Lighting Considerations

Solar bollard lights and larger solar systems require specific pole orientations and mounting configurations:

- Solar panels must face north in Australia

- Optimal tilt angles: 23 degrees in northern states, 43 degrees in southern states

Luminaire Quantity Per Pole

Traditional configurations include:

- Single luminaire for residential streets

- Dual luminaires for commercial applications

- Quad luminaires for large area coverage

- Custom arrays for sports facilities

Each additional luminaire increases wind load (EPA) and structural requirements, directly influencing pole diameter and wall thickness specifications.

Step 2: Assess Environmental Conditions and Structural Loads

Australia’s climate ranges from tropical cyclones to alpine blizzards. Correctly matching pole strength to these conditions is therefore the critical second step in How To Choose The Right Pole for your Project.

How to calculate load-bearing capacity?

- List every permanent attachment.

- LED luminaires (5–25 kg each, >50 kg for large sports fittings)

- Brackets and arms (10–50 kg; heavy-duty up to 100 kg)

- Cameras, sensors, banners and signage

- Add a 1.5 × safety factor. Compensates for installation tolerances and future equipment.

- Check load distribution. Eccentric or asymmetrical loads create bending moments that often require larger diameters or thicker walls.

How to assess wind load and other forces?

| Item | Method |

|---|---|

| Effective Projected Area (EPA) | Sum the frontal area of pole + all attachments. |

| Design wind speed | Use regional data in AS/NZS 1170.2 and verify with local council records. |

| Topography | Hills, escarpments and open coastal plains increase wind pressure. |

| Dynamic effects | Vibration in open car parks, bridges or airport aprons can exceed static loads. |

| Seismic zones | Allow flexibility in foundations where required. |

Australian wind design is ultimately governed by Standards Australia – see the overview at Standards Australia.

What environmental conditions will the pole face?

- Coastal exposure (<1 km from ocean): salt spray can corrode unprotected steel up to ten times faster than inland sites.

- Industrial pollutants: sulphur and chemical vapours accelerate coating breakdown.

- High UV radiation: specify UV-stable powder coats or anodising to avoid chalking and colour fade.

- Soil type: clay needs deeper footings, sand needs larger diameters, rock demands pre-drilling but offers excellent long-term stability.

Rapid checklist

- Coastal? ‑ choose aluminium or marine-grade coatings.

- Open terrain? ‑ favour round tapered poles to minimise vibration.

- High seismic risk? ‑ design flexible foundations and connections.

By working through these four short lists you remove the biggest causes of premature failure while keeping calculations concise and verifiable.

Step 3: How To Choose The Right Pole Material for Your Project

Material selection defines lifespan, maintenance cost, and sustainability outcomes. The comparison below condenses the key facts engineers need when specifying poles for Australian sites.

Comparing Common Pole Materials

| Material | Life Expectancy | Corrosion Resistance | Relative Weight | Typical Applications |

|---|---|---|---|---|

| Aluminium | 50 + years | Excellent (self-healing oxide layer) | ★★★★☆ (light) | Coastal streets, architectural precincts, smart-city poles |

| Steel | 15–30 years* | Fair–Good (needs coatings) | ★★☆☆☆ (heavy) | High-mast sports lighting, heavy load sites |

| Composite | 70 + years | Excellent | ★★★★☆ (light) | Electrically sensitive, extreme corrosion zones |

| Timber | 20–30 years | Poor without treatment | ★★★☆☆ | Heritage areas, parkland aesthetics |

*Service life depends on galvanising and maintenance schedules.

Aluminium Poles – sustainable and low maintenance

- Natural oxide film prevents rust, making aluminium ideal near salt water or chemical plants.

- One-third the weight of steel, reducing crane size, footing volume, and installation risk.

- 95 % recyclable at end-of-life, supporting circular-economy targets.

Steel Poles – best for very high loads

- High tensile strength manages large LED arrays and accessories above 30 m.

- Widely available and cost-effective up-front, but requires hot-dip galvanising plus periodic re-coating in coastal or industrial zones.

Composite and Timber – niche but valuable

- Composite: non-conductive, immune to rust, excellent for electrical substations or aggressive chemical environments.

- Timber: visually blends with natural landscapes; however, weight and ongoing treatment increase whole-of-life cost.

QUICK TIP

Unless a project demands extreme height or specialised heritage aesthetics, aluminium usually delivers the best balance of durability, handling, and sustainability for Australian conditions.

By choosing the appropriate material at this stage you eliminate costly retrofit coatings, premature replacements, and unnecessary embodied carbon.

Step 4: Plan for Installation, Compliance, and Aesthetics

Installation planning determines project success, safety outcomes, and long-term performance. Proper installation methods ensure structural integrity while minimizing costs and construction disruption.

Regulatory compliance protects public safety and ensures project acceptance by authorities. Australian Standards provide comprehensive guidelines for structural design, electrical safety, and lighting performance.

What are the installation requirements and methods?

Direct Burial Installation Direct burial involves embedding the pole directly into the ground with concrete backfill. This method suits:

- Timber poles with appropriate preservative treatment

- Specific composite poles designed for direct burial

- Temporary installations requiring rapid deployment

- Locations with suitable soil conditions

Direct Burial Considerations:

- Requires minimum burial depth of 10% of above-ground height plus 2 feet

- Soil conditions must provide adequate bearing capacity

- Drainage considerations prevent water accumulation around pole base

- Future pole replacement requires complete excavation

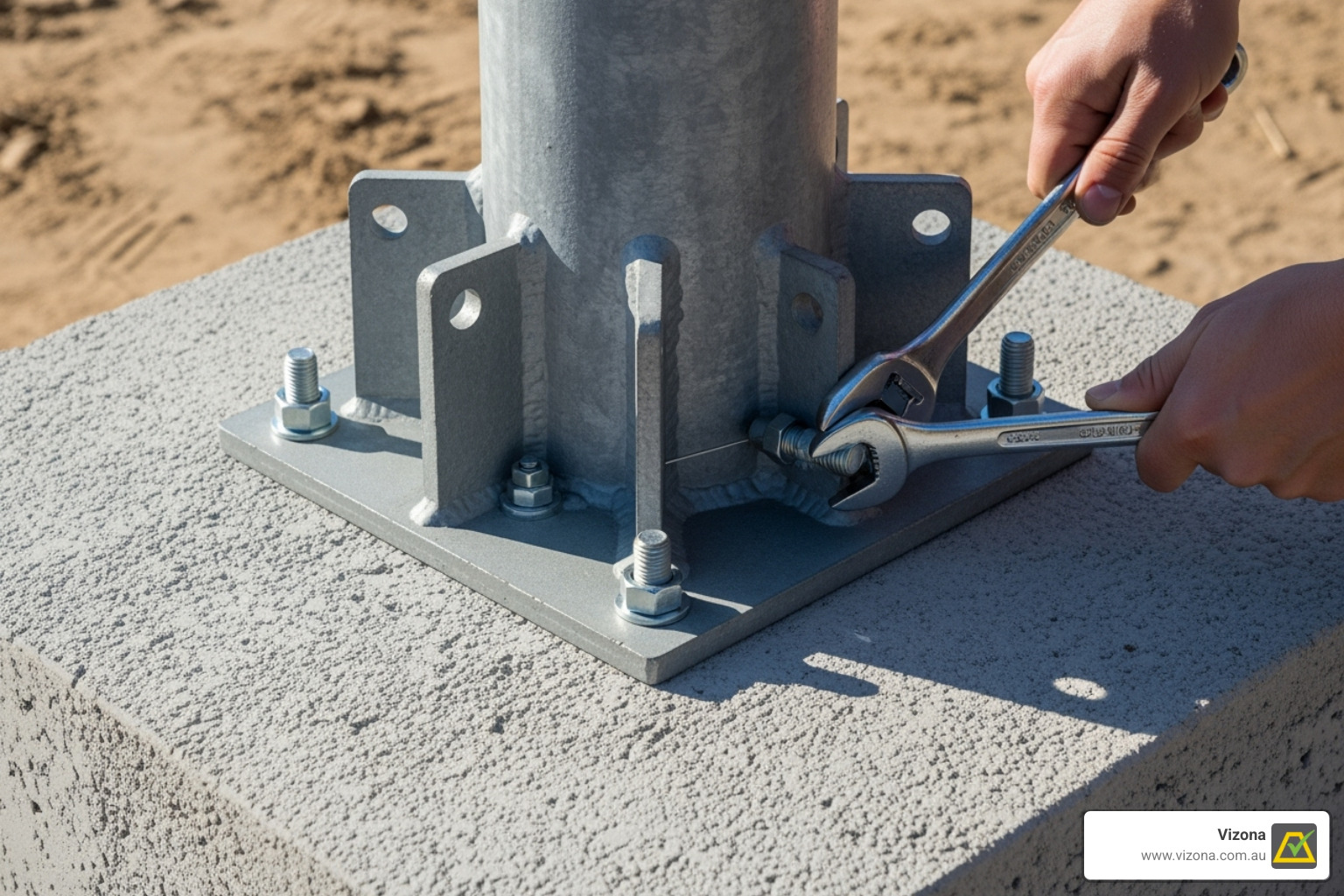

Flange Base Mounting Flange mounting represents the most common installation method for metal poles. The process involves:

- Foundation Preparation: Excavate and form concrete foundation according to engineering specifications

- Anchor Bolt Installation: Position anchor bolts using manufacturer-supplied templates

- Concrete Placement: Pour concrete ensuring proper consolidation and curing

- Pole Mounting: Bolt pole to foundation using specified torque values

Flange Mounting Advantages:

- Easier pole replacement without foundation disturbance

- Superior load transfer to foundation

- Accessibility for maintenance and inspection

- Compatibility with all metal pole types

Foundation Design Requirements Foundation specifications depend on:

- Pole height and loading conditions

- Soil bearing capacity and type

- Frost depth and seismic considerations

- Local building code requirements

Standard Foundation Formula: For poles up to 18 feet: 3 feet deep x 2 feet wide Add 1 foot depth and 1 foot width for every 5 feet above 18 feet

Installation Equipment and Costs Equipment requirements vary by pole size and installation method:

- Small Poles (under 20 feet): Mobile crane or telehandler sufficient

- Medium Poles (20-40 feet): Truck-mounted crane required

- Large Poles (over 40 feet): Specialized heavy-lift equipment necessary

Installation costs typically include:

- Material delivery and handling

- Foundation excavation and concrete work

- Crane rental and operator costs

- Electrical connections and commissioning

- Site restoration and cleanup

How to ensure regulatory and safety compliance?

Key Compliance Requirements:

- Adherence to Australian Standards AS/NZS 1170.2 for wind loads

- Compliance with AS/NZS 1158 series for lighting design

- Local council development approval and permits

- Electrical safety certification for all 240V lighting products

- Work health and safety requirements during installation

Australian Standards Framework AS/NZS 1170.2 provides comprehensive wind load calculations including:

- Regional wind speed classifications

- Terrain category effects on wind exposure

- Importance level factors for critical infrastructure

- Dynamic response factors for flexible structures

Lighting Performance Standards AS/NZS 1158 series specifies:

- Illumination levels for different road classifications

- Uniformity ratios for safe visibility

- Glare limitation requirements

- Energy efficiency targets

Electrical Safety Requirements All 240-volt lighting products must be certified by SAA Approvals Pty Ltd, ensuring:

- Protection against electrical hazards

- Weather resistance for outdoor applications

- EMC compliance for electronic components

- Quality assurance through recognized testing

Work Health and Safety Compliance Installation activities must comply with WHS regulations including:

- Risk assessment and safety planning

- Qualified personnel and equipment certification

- Fall protection and electrical safety measures

- Emergency response procedures

How to choose the right features, accessories, and aesthetics for your project?

Pole Shape and Configuration Pole geometry affects both performance and aesthetics:

Round Poles:

- Superior wind resistance due to aerodynamic shape

- Even stress distribution eliminates stress concentration points

- Traditional appearance suitable for most applications

- Available in straight or tapered configurations

Square Poles:

- Modern architectural appearance

- Flat surfaces accommodate signage and accessories

- Higher wind loads due to sharp edges

- Stress concentration at corners requires careful design

Tapered vs. Straight Profiles:

- Tapered poles provide superior strength-to-weight ratios

- Straight poles offer simpler fabrication and lower costs

- Aesthetic preferences vary by application and setting

Finish Options and Durability Protective finishes determine appearance retention and longevity:

Powder Coating:

- Excellent durability and color retention

- Wide range of colors and textures available

- Superior adhesion and impact resistance

- 15-25 year performance expectation

Anodizing (Aluminium Only):

- Integral oxide layer provides permanent protection

- Natural metallic appearance or colored options

- Exceptional corrosion resistance

- 30+ year performance in most environments

Mounting Hardware and Accessories Modern poles must accommodate diverse equipment:

- Luminaire Mounting: Arms, brackets, and direct mounting options

- Smart City Integration: Provisions for cameras, sensors, and communication equipment

- Decorative Elements: Banner arms, planters, and architectural features

- Utility Integration: Power outlets, emergency call boxes, and signage

Aesthetic Integration Principles Successful pole selection considers:

- Contextual Appropriateness: Matching architectural styles and urban character

- Scale Relationships: Proper proportion to surrounding buildings and landscapes

- Color Coordination: Harmonizing with existing infrastructure and design guidelines

- Future Adaptability: Accommodation for evolving technology and community needs

Frequently Asked Questions about Choosing a Project Pole

What is the most important factor when choosing a pole?

When considering How To Choose The Right Pole for your Project, structural integrity stands as the cornerstone of safe pole selection. While aesthetics, cost, and installation methods all play important roles, ensuring your pole can withstand the forces it will face throughout its service life protects public safety and prevents costly failures.

Wind load capacity forms the foundation of this structural assessment. The Effective Projected Area (EPA) calculation determines how much surface area your pole and all its equipment present to wind forces. This includes not just the pole itself, but every luminaire, bracket, camera, banner, and sensor that will be mounted.

Weight-bearing capability works hand-in-hand with wind resistance. Your pole must support the static weight of all equipment plus the dynamic forces created by wind, vibration, and thermal expansion. A pole that seems adequate for today's lighting might fail when additional smart city equipment is added later.

Structural failure creates catastrophic consequences. Property damage, personal injury, and liability exposure far exceed any initial savings from undersized poles. Professional structural analysis considers maximum expected wind speeds, total equipment loads including future additions, soil conditions, and seismic activity.

The interconnected nature of pole selection means that structural requirements influence every other decision. Material choice, foundation design, and installation methods all stem from the fundamental structural demands of your specific location and application.

How do I determine the correct pole height for my project?

Professional lighting design simulation provides the most accurate method for determining optimal pole height. This process goes far beyond simple rules of thumb, calculating the precise height needed to achieve compliant illumination levels, uniform light distribution, and proper glare control for your specific application.

Lighting simulation software considers photometric data from actual luminaires, site geometry, surrounding structures, and applicable Australian Standards. The simulation process reveals how different pole heights affect light patterns, uniformity ratios, and energy efficiency across your entire project area.

General height principles provide useful starting points for initial planning. Residential streets typically require 15-20 feet for narrow roads, increasing to 25-30 feet for wider boulevards. Commercial car parks commonly use 20-25 foot poles, with heights up to 30 feet for large open areas requiring extensive coverage.

Sports facilities demand specialized height considerations. Tennis courts typically need 22.8-foot light mounting heights, achieved with 20-foot poles plus mounting adapters. Baseball and other ball field lighting usually starts at 40 feet and can exceed 70 feet for major competitive facilities.

Pedestrian areas prioritize human scale and comfort, typically using 9-14 foot poles. These installations focus on creating safe, welcoming environments without the intimidating scale of vehicular lighting.

The relationship between pole height and spacing follows established principles. Pole spacing should generally not exceed 3-4 times the mounting height for optimal uniformity. Taller poles cover larger areas but may create uniformity challenges that require careful photometric analysis.

Economic considerations balance pole height against the total number of poles required. Taller poles reduce the quantity needed but increase individual pole costs and installation complexity. Professional simulation reveals the optimal balance for your specific project.

Why is pole material so important for Australian conditions?

Australia's diverse environmental challenges make material selection critical for long-term pole performance and cost-effectiveness. Our harsh conditions accelerate degradation processes that might take decades to appear in milder climates, making the wrong material choice particularly expensive.

Coastal environments present the most aggressive conditions for pole materials. Salt spray accelerates corrosion rates dramatically, with steel poles experiencing up to 10 times faster degradation near saltwater compared to inland locations. The constant moisture and salt create an electrochemical environment that attacks protective coatings and the underlying metal.

Extreme UV exposure across much of Australia degrades materials and protective systems faster than in other climates. Our intense solar radiation breaks down polymer components, fades colors, and weakens protective coatings. Quality materials and finishes specifically designed for high-UV environments maintain their protective properties and appearance over decades.

Temperature extremes create thermal stress cycles that fatigue materials and protective systems. The wide temperature variations between day and night, and between seasons, cause expansion and contraction that can crack coatings, loosen connections, and create stress concentration points.

Severe weather events including cyclones, severe thunderstorms, and extreme wind events test pole structural integrity beyond normal design parameters. Australian engineering standards reflect these environmental realities through specific design requirements that exceed those in many other countries.

Aluminium's superior performance in Australian conditions explains its growing popularity for critical installations. The material's natural corrosion resistance, UV stability, and thermal properties provide exceptional durability across our diverse climate zones. This performance translates directly to extended service life and reduced maintenance requirements.

Lifecycle cost analysis reveals the true value of proper material selection. While aluminium poles may cost more initially than steel alternatives, their 50+ year service life compared to 15-30 years for steel creates significant long-term savings. Reduced maintenance, fewer replacements, and superior recyclability support both economic and environmental objectives.

The material choice for How To Choose The Right Pole for your Project ultimately determines whether your installation will provide decades of reliable service or require costly maintenance and premature replacement. Understanding Australian conditions ensures your material selection supports long-term project success.

Conclusion

Selecting the right pole for your project demands careful consideration of multiple interconnected factors that determine both immediate success and long-term performance. How To Choose The Right Pole for your Project becomes significantly easier when you follow a systematic approach that prioritises safety, durability, and regulatory compliance.

The foundation of successful pole selection lies in understanding your specific application requirements. Whether you're planning street lighting upgrades, sports facility development, or decorative urban lighting, each application presents unique challenges that influence material choice, height requirements, and structural specifications.

The Critical Role of Material Selection

Material choice fundamentally shapes project outcomes and lifecycle costs. Aluminium poles consistently deliver superior performance in Australian conditions, offering exceptional corrosion resistance and 50+ year lifespans that justify their investment. The material's natural ability to withstand coastal salt spray, industrial pollutants, and extreme UV exposure makes it particularly suitable for our diverse environmental conditions.

Steel poles remain the preferred choice for applications requiring maximum structural capacity and heavy load-bearing capability. Their superior strength characteristics make them ideal for high mounting heights and multiple luminaire configurations, though proper coating systems are essential for longevity.

Composite materials serve specialized requirements where electrical safety or extreme corrosion resistance takes precedence, offering 70+ year lifespans with minimal maintenance requirements.

Environmental Considerations Drive Performance

Australia's challenging environmental conditions demand materials and designs that can withstand severe weather events, temperature extremes, and harsh atmospheric conditions. Understanding your site's specific environmental challenges—from cyclonic activity in northern regions to salt spray in coastal areas—directly influences material selection and protective system requirements.

Wind load calculations using Effective Projected Area (EPA) methodology ensure structural integrity under extreme conditions. This technical analysis, combined with proper foundation design and installation methods, creates the structural foundation for safe, long-lasting installations.

Regulatory Compliance and Safety Standards

Australian Standards provide comprehensive guidance for structural design, lighting performance, and electrical safety requirements. AS/NZS 1170.2 wind load calculations and AS/NZS 1158 lighting standards ensure installations meet safety requirements while delivering optimal performance.

All 240-volt lighting products require SAA Approvals Pty Ltd certification, ensuring electrical safety and weather resistance for outdoor applications. This certification process protects both public safety and project investment through rigorous testing and quality assurance.

Sustainability and Long-term Value

Modern pole selection increasingly emphasises sustainability through recyclable materials, energy-efficient LED technology, and extended service life. Aluminium's 95% recyclability supports circular economy principles while delivering superior performance over traditional materials.

LED integration has transformed pole requirements, with lighter luminaires enabling optimized designs and up to 75% energy reductions compared to traditional systems. Smart lighting controls and solar options further improve sustainability while reducing operational costs.

Vizona's Comprehensive Approach

At Vizona, our 20+ years of infrastructure experience guides every pole selection decision. We understand that How To Choose The Right Pole for your Project requires balancing technical performance, regulatory compliance, and economic considerations while supporting Australia's sustainability objectives.

Our technical expertise encompasses structural engineering, lighting design, and regulatory compliance to deliver complete solutions custom to Australian conditions. From initial design consultation through installation and commissioning, we provide the technical support and product knowledge necessary for optimal project outcomes.

Whether your project involves community sports facilities, major infrastructure developments, or decorative urban installations, our team delivers the expertise and quality products that ensure long-term success. Our commitment to sustainable materials, innovative LED technology, and comprehensive technical support makes us your trusted partner for lighting infrastructure projects across Australia.

Explore our comprehensive street and area lighting solutions to find how our expertise in pole selection and lighting design can benefit your next project. Contact our technical team for project-specific guidance and recommendations custom to your unique requirements.